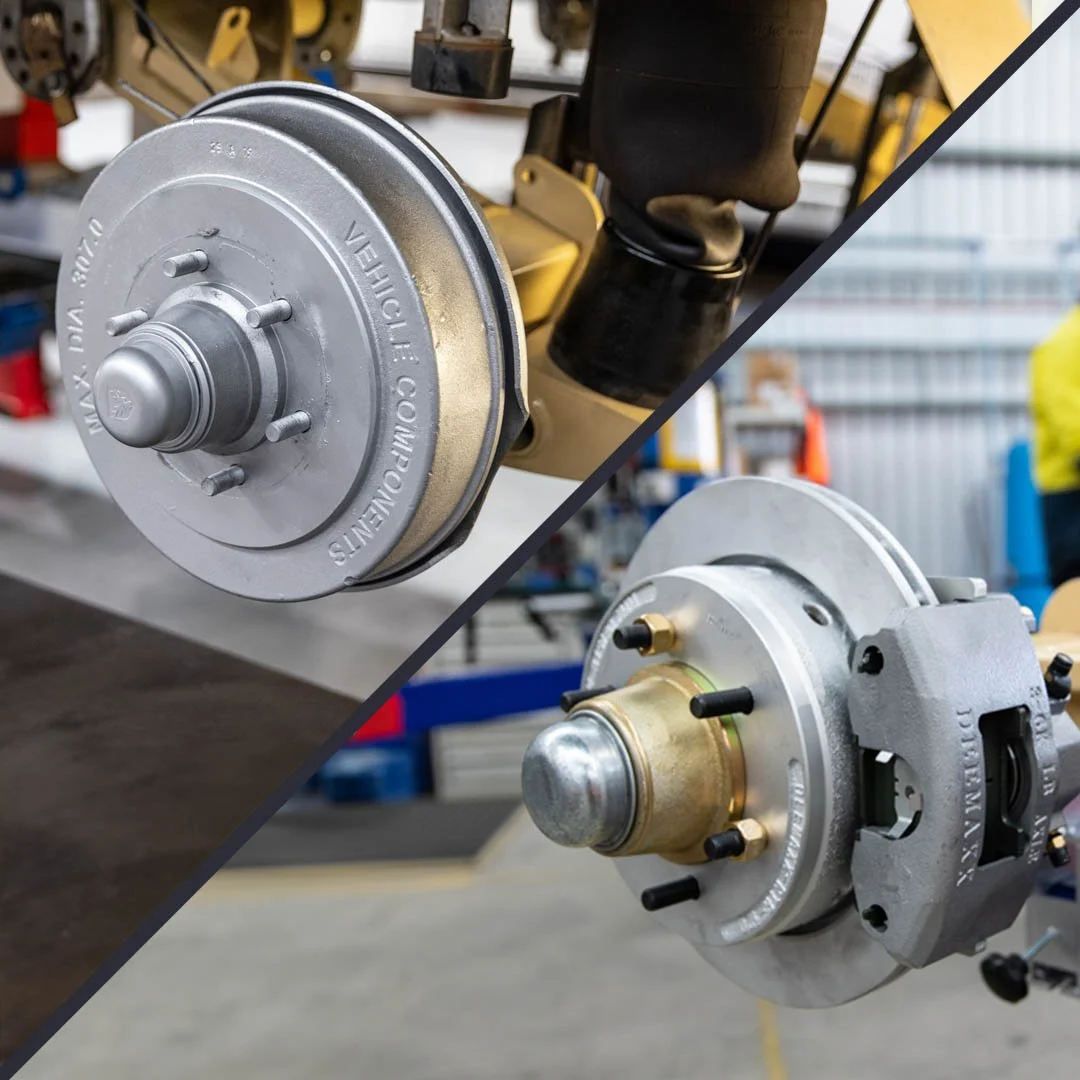

Drum-to-Disc Brake Conversions

Upgrade Your Braking Performance

ATX and 12” XT Suspension Systems Only

If you’re running standard drum brakes on your caravan, camper, or trailer, it might be time to step your game up. At the Cruisemaster Towing Performance Centre, we offer 12” drum-to-disc brake conversions that deliver stronger, smoother, and more reliable braking — especially under heavy loads or in tough off-road conditions.

Superior Stopping Power – Improved braking efficiency and reduced stopping distances give you greater control when towing.

Better Heat Management – Disc brakes dissipate heat more effectively, reducing brake fade on steep descents or during repeated stops.

Simpler Maintenance – Easier inspection and replacement of pads, meaning less downtime and more time on the road.

Improved Safety – Consistent braking performance gives you confidence when towing through varied terrain.

Expert Installation, Backed by Cruisemaster

Our experienced technicians are specialists in caravan and trailer braking systems. Every conversion is completed to Australian Design Rules (ADR) compliance standards and is fully tested before you hit the road.

Set for Adventure

Upgrading to disc brakes is more than just a performance boost — it’s peace of mind for every journey. Whether you’re crossing the Outback or cruising the coast, our conversions ensure your rig is Serviced. Safe. Set for Adventure!

Looking for a safety focused brake upgrade?

Consider a drum brake upgrade to a Cruisemaster ABS Enabled system paired with Bosch TSC (Trailer Safety Control).

Frequently Asked Questions

-

No, Cruisemaster ATX and XT Suspension Systems are designed to utilise the same arm and stub axle between both 12” Drum and Disc brake systems. It is a relatively simple process to remove the drum hardware and replace with Disc Brake Hardware.

-

1. Brake Rotor (Disc)

A machined metal disc mounted to the hub.

Spins with the trailer wheel.

Provides the friction surface for the brake pads to clamp against.

2. Brake Caliper

Houses the hydraulic piston(s) and brake pads.

Squeezes the pads against the rotor when pressurised hydraulic fluid is applied.

Can be single piston or twin piston depending on load rating.

3. Brake Pads

Friction material mounted inside the caliper.

Contact the disc to create braking force.

Wear items that need regular inspection and replacement.

4. Hydraulic Piston(s)

Inside the caliper, moved by hydraulic fluid pressure.

Converts hydraulic pressure into mechanical clamping force on the pads.

5. Hydraulic Lines & Fittings

High-pressure lines carrying brake fluid between the actuator and calipers.

Includes hoses, steel lines, unions, and bleed nipples.

6. Electric Over Hydraulic Actuator (EOH)

The “brain” of the system.

Receives an electrical signal from the tow vehicle’s brake controller.

Converts that signal into hydraulic pressure, pushing fluid to the calipers.

7. Brake Controller (in Tow Vehicle)

Installed in the car.

Detects when the brake pedal is pressed and sends a proportional signal to the trailer’s actuator.

Some vehicles have this integrated from factory, others need aftermarket units.

8. Fluid Reservoir

Part of the actuator.

Stores brake fluid and ensures the system stays topped up under pressure.

-

The car sends an electrical signal → the actuator builds hydraulic pressure → fluid travels down lines → pistons in the caliper push pads against the rotor → friction slows the trailer.

-

No, your existing brake controller will continue to work with a Disc Brake setup. With the improved brake performance of disc brakes you will likely need to adjust down the controller setting.